Connor Ambrose

Bachelor of Industrial Design, Honours, Final Year

Connor Ambrose is an Industrial Design Honours fourth-year student at Western Sydney University, originally studying for a Design and Technology degree but switched degrees to extend his study in the field. During his studies, he has branched out to follow his interests by studying business and entrepreneurial subjects to help open up potential business opportunities for his future career. His interest in helping people in need helped to form and shape the project and its prosthetic design as it was designed so that everyone could have an equal chance at life.

Prosthetics for the Amputee Farmers of India

Prosthetics are present in most parts of the world, especially in the developed world where they are easy to access, affordable, and have high functionality, allowing their users to live independent fulfilling lives. However, this isn’t the same in developing countries like India, as prosthetics aren’t as available as they are in the developed world.

The prosthetics that are cheaply made, have limited functionality, aren’t suited for jobs with manual labour, and don’t have a long product life expectancy due to the infrastructure and environment of India. This problem is amplified for the people living in the rural parts of India, who mainly work as farmers and cannot afford or access the prosthetics they need resulting in amputees having a poorer life quality that is dependent on others.

The aim of this project is to create a cost-effective prosthetic that can be implemented in rural parts of India, that is suited for the environments of India, allows for a long product life span, and is suited for farm work.

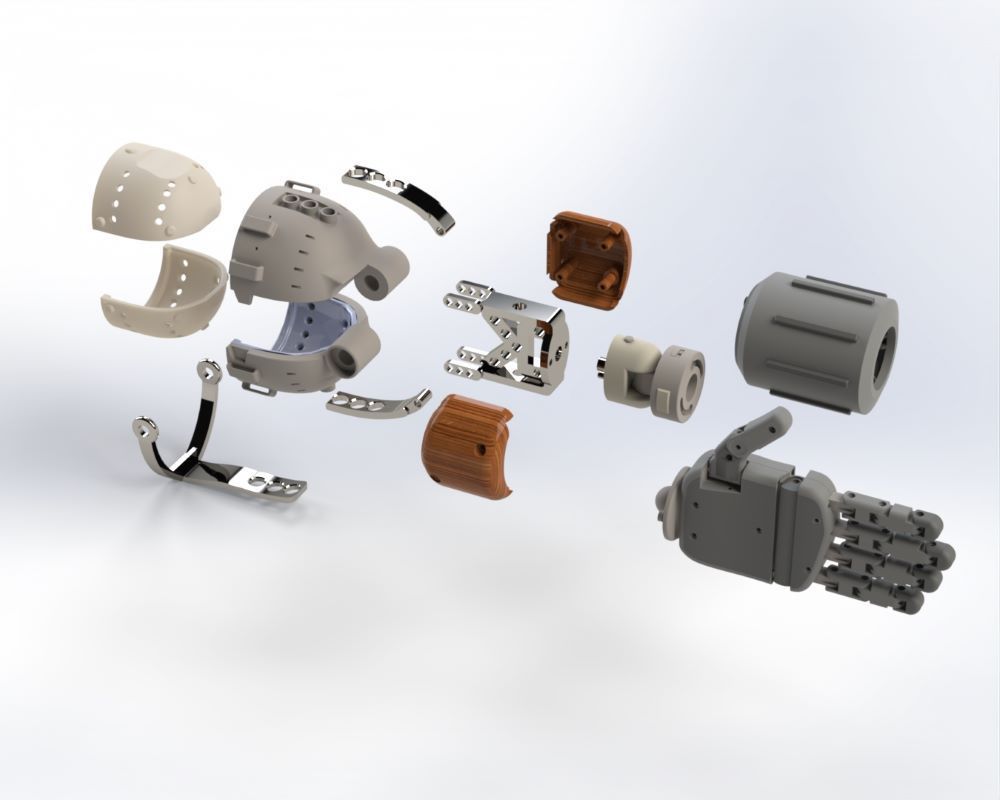

The final design is a forearm prosthetic, that is durable, has a longer life span, is more functional, and is suited for farming environments than other prosthetics on the market. The design incorporates a do-it-yourself aspect which will allow users to build the prosthetic themselves, allowing them to learn how the device goes together which can help with future repairs or modifications and help them create a connection with their prosthetic. The prosthetic solution is also modular which allows for ease of assembly and the replacement of parts, along with the interchangeability of hand attachments that are designed for specialized tasks.

The design will have an effective implementation in India, due to the variety of features that make the design ideal for farming environments, the design incorporates a wide range of users' ergonomics, with its adjustability and silicone inserts and air circulation which allows users to wear the device for longer periods of time. The design also incorporates sustainability through the usage of recycled materials and the encouragement of replacing parts, instead of the whole device, allowing the device to be with the user for life so that they won't need another prosthetic.