Sara Rufaeel

Bachelor of Engineering, Honours

Sara Rufaeel is currently in the final phase of her Civil Engineering studies, entering her fourth and last year. Originally from Iraq, she is Inspired by her parents' resilience in overcoming cultural and language challenges for her education and therefore, Sara is committed to excelling in her field. With a year of experience as a Stormwater Engineer, she integrates her passion for science with her engineering pursuits. Sara's determination, strong work ethic, and exceptional problem-solving skills are evident as she tackles her engineering responsibilities with dedication, both in collaborative team environments and when working independently.

Producing and Characterising Elemental Thin Film Coatings for use in SEM Analysis

Embarking on the frontiers of Scanning Electron Microscopy (SEM), my research delves into the often-overlooked realm of coating thickness and its profound influence on the crystalline structure of samples. While carbon coatings have traditionally been the focus, this study expands the horizon to include metallic elements like Gold (Au) and Chromium (Cr). The motivation stems from the challenges posed in imaging electrically non-conductive samples, where distortion and reduced visibility often hinder accurate analysis. Metallic coatings, with their mere nanometre-scale thickness, emerge as powerful solutions, enhancing sample conductivity, contrast, and overall imaging integrity.

The heart of the investigation lies in the exploration of gold and chromium coatings on silicon substrates, with meticulous variation in coating times and thicknesses. Gold, a stellar electrical conductor, proves ideal for imaging electrically non-conductive samples, particularly relevant in the realm of biological materials. Its conductivity, resistance to oxidation, and stable coating properties make it a standout choice. Simultaneously, chromium offers an alternative avenue for improved SEM image quality and enhanced conductivity.

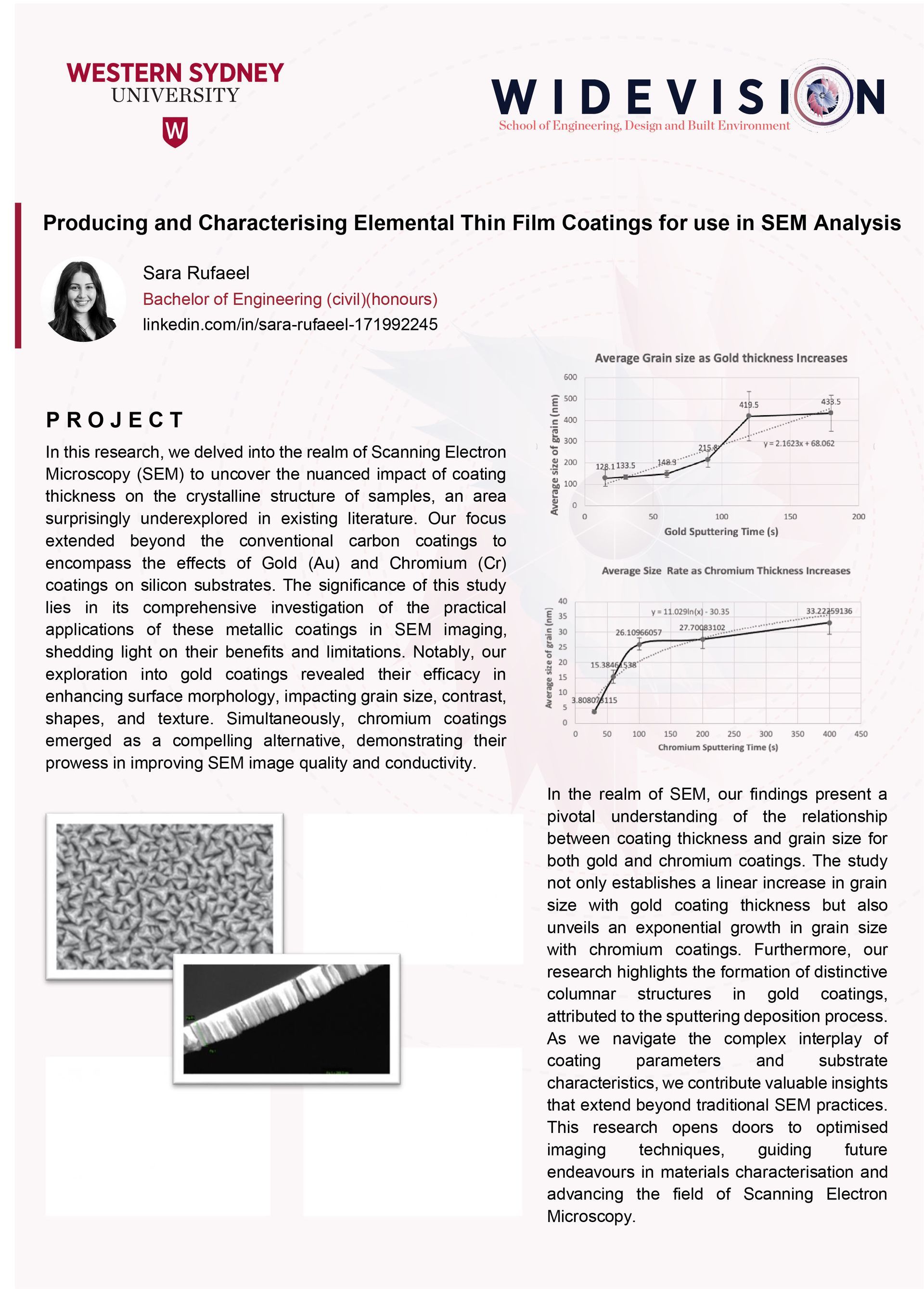

The methodology, employing cutting-edge techniques such as the Leica EM SCD005 sputter coating device and Zeiss SEM instrument, ensures a rigorous and comprehensive analysis. The results unfold a captivating narrative, revealing a direct correlation between coating thickness and grain size. Gold coatings exhibit a linear increase in grain size, attributed to factors like surface diffusion, small nuclei presence, and coalescence of neighbouring grains. In contrast, chromium coatings showcase an exponential growth in grain size, accompanied by distinctive tetrahedral shapes. Beyond the analysis of SEM images, the study investigates the columns created by metal deposition, shedding light on the complex interplay of sputtering variables. Additionally, concerns regarding thermal expansion mismatch are addressed, with a pragmatic perspective on managing potential issues.

In conclusion, this research contributes a significant stride forward in understanding the interplay between coating thickness and sample morphology, offering practical insights into the applications of gold and chromium coatings in SEM imaging. The findings not only deepen our comprehension of nanoscale structures but also pave the way for optimised imaging techniques and future advancements in materials characterisation.